Shift Bearings

Take this page out to your manual MR2 and have a sit in your drivers seat. Very gently push your gear stick forwards and backwards. You will probably have a few centimetres worth of slop or play. The following DIY will remove nearly all of it and will work equally well on both MKI (AW11) and MKII (SW20) MR2’s.

What you need

You will need some tools:

- sharp knife

- flathead screwdriver

- jack/axle stands and jack

- safety glasses

…and some material:

1 skateboard / rollerblade bearing. Bearings out of an old pair of skates (free!) – any ABEC rating will work fine, so get the cheapest. This exact same kit of parts is sold on E-bay and MR2 shops for $30USD - $40USD!!!

(FlyingbrickNathan sells the bearing and washers for $5 shipped.)

4 random washers with a hole diameter similar (larger, not smaller) than that of the bearing hole. Bearing hole is 1/2" diameter.

What you do

- Jack up the rear of your car and put it up on stands.

- Put on your safety glasses, you’ll have a lot of crud falling onto your face.

- Slide under your car. Enter from the left side of the car, in front of the rear wheel. If it hasn’t already fallen off, remove the small plastic undertray located at the front of the engine bay.

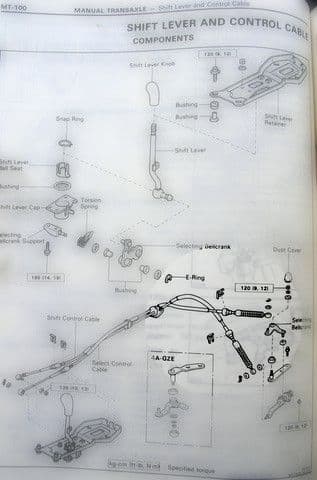

- Look straight up as you go under and you will see two shift levers and the shift cables. The bottom levers bushing handles the front/back movement of your gearstick and seems to be the only one which wears out appreciably. The BGB page might give you some idea of what you’re looking for.

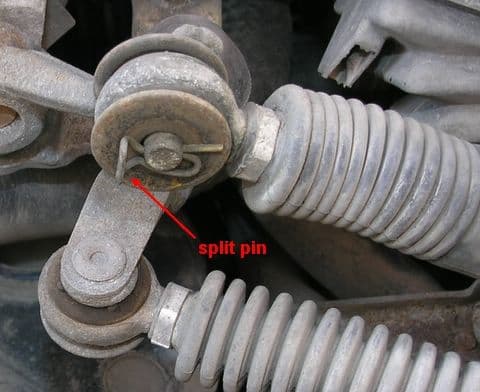

- Use a screwdriver to remove the split pin. Remove the large black washer and put it someplace safe. Pull the cable end off the shaft. Pull the second black washer off the shaft and put it beside the first.

- The rubber bush can be a little nasty to get out of the cable end. Put a screwdriver through the hole on the bushing and lever it out of the shift lever. You may need to cut the rubber inside the bushing. Have a look at the bushing and its brass insert. It’s probably oval which is what alows the slop.

- Take your bearing and make sure it slides nicely onto the shaft. If the bearing is a tight fit, you might need to scrap some crud off the shaft with a knife or some sand paper.

- Using your knife, clean out the cable end. Push your bearing slowly and evenly into place. It might take a bit of pushing on each side to slowly edge it in. Sometimes freezing the bearing first to make it a tad smaller helps with the fit.

- Assemble the unit in the reverse of before. Big black washer -> bearing / cable end -> big black washer.

- You will probably have 5-10mm of space on the shaft between black washer and split pin hole. You want to fill this space with your random washers. Don’t pack the washers on too tightly. Remember the big black washer on each side (its already on the assembly). You don’t want the cable end sliding off the bearing and shaft.

- Put the pin back in and make sure it won’t fall back out.

Thats it. Finished, done.